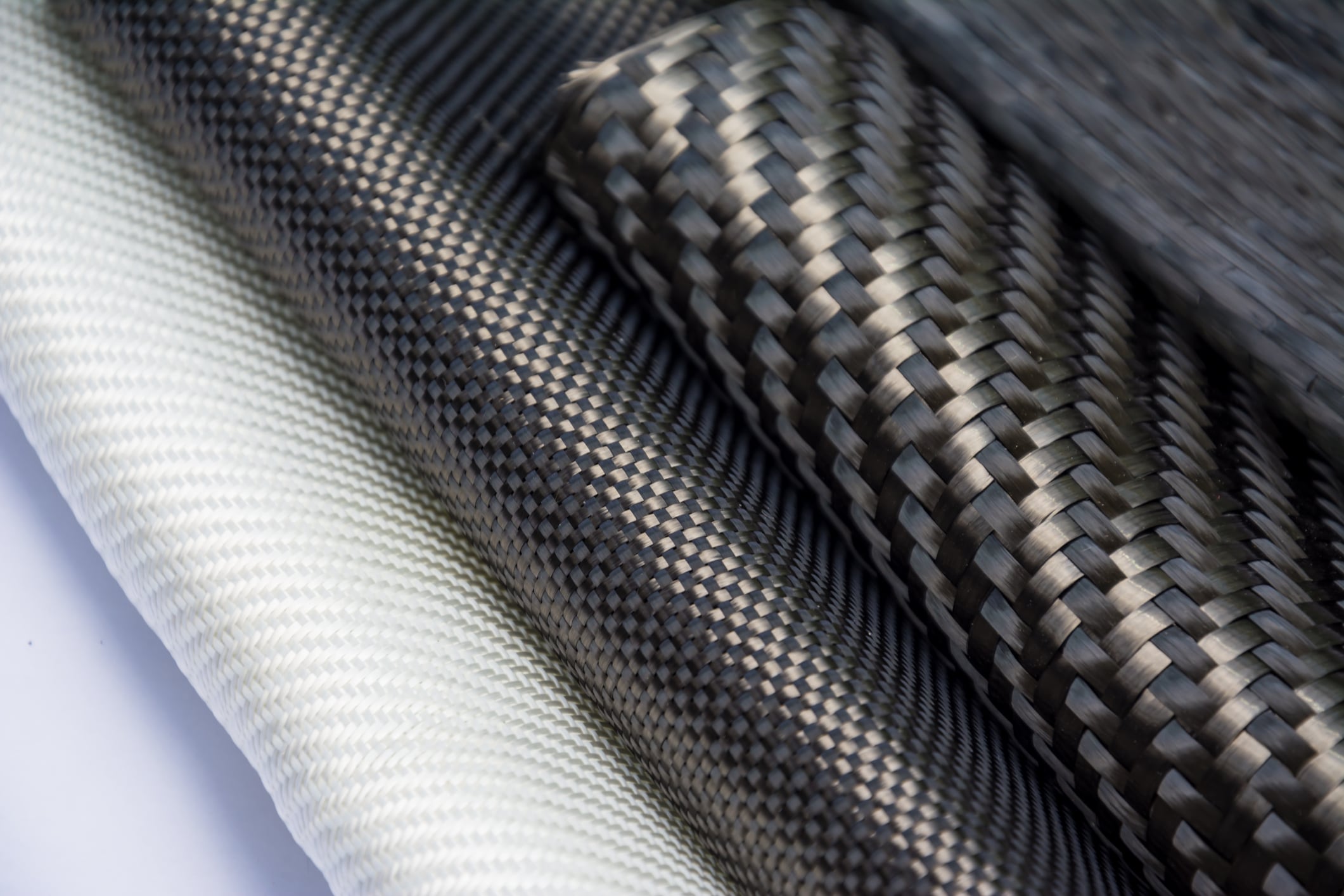

Long and Short Technical Hemp Fibers

Long and short technical hemp fibers are produced from the outer part of the hemp stalk, known as the bast layer. These fibers are considered to be among the strongest of all natural bast fibers and have been used in the production of textiles and paper for centuries.

Strength and Versatility

Technical hemp fibers provide effective solutions to a wide variety of industries. With an extraordinary strength to weight ratio, these fibers are used to enhance composite panels commonly used in automobiles, airplanes, boats and even building structures. Hemp fibers increase the strength of these products while significantly reducing weight and increasing efficiency.

Best Hemp Fibers Available

ELI’s state-of-the-art processing facility minimizes damage to technical fibers during processing, allowing us to produce the strongest technical hemp fibers available. Our fibers meet the most stringent standards to be used in the manufacturing of a wide array of products from textiles, composites, building materials, and much more.

ELI Delivers What Our Customers' Demand

ELI can customize hemp fiber width and length according to our customers’ needs. Our technical fibers can be produced between 40mm and 350mm in length. Our high-quality technical fibers often contain less than 1% (and always less than 3%) of hurd material.

Contact Us

We’d love to hear from you! Whether you are seeking answers to questions, want to share industry insights, or would like to learn more about how ELI can help you or your business harness the power of industrial hemp, please complete this contact form and a member of our team will be in touch!

"*" indicates required fields